The Difference between Nozzle and Silent Check Valves

Why a Nozzle Check Valve Can be a Silent Check Valve but a Silent Check Valve can never be a Nozzle Check Valve

Terminology:

Check Valve: Check Valves is used synonymously to describe Non-Return Valves as the term Non-Return Valves was used to describe Reflux Valves synonymously two generations ago.

Nozzle Check Valves: Are Co-Axial Check Valves that utilises the Venturi Principal to reduce Headloss and is spring loaded to reduce Waterhammer.

Silent Check Valves: Are Co-Axial Check Valves that are spring loaded for rapid closure but have high Headlosses.

Introduction

A well designed Check Valve is essential in any pressurized pipeline application in order to protect pumps from reverse flow and pipelines from Waterhammer. In addition, the Check Valve should be reasonably priced relevant to the application and have a low headloss characteristic to reduce power consumption.

The specification of Nozzle Check and Silent Check Valves have grown in popularity as part of a Pipeline Surge and Waterhammer protection strategy because of their Non-Slam characteristics. In some cases, the specifications specify either a Silent or Nozzle Check Valve as if though these designs are interchangeable.

Though both valves are Co-Axial designs, they differ substantially in their design approach and therefore their impact on the Life Cycle Costing of a pipeline.

This document briefly discusses the Check Valve Slam phenomenon and the reason why Nozzle and Silent Check Valves are suited for Waterhammer protection. However, it points out that when the complete Life Cycle Costing of the pipeline is taken into account that a Nozzle Check provides a more holistic solution and a lower cost of ownership than a Silent Check Valve in essence, it explains why a Nozzle Check Valve can be a Silent Check Valve but why a Silent Check Valve cannot be Nozzle Check Valve.

Check Valve Slam

The potential for a Check Valve to either create Waterhammer (which is often termed Check Valve Slam) or, prevent Waterhammer is highly dependant on the Check Valve design, the system configuration and the pipeline profile.

Check Valve slam occurs when the valve closing member is slammed suddenly into its seat by flow reversal. Transients created in this manner are damaging to both the valve and the system. Check Valve Slam depends on many interrelated factors in addition to the Check Valve design. The causes or aggravation of this phenomenon can be split into two broad sectors namely:

System Design

Each system design is unique, as the factors that may cause Check Valve slam in one system may be totally different to those that cause slam for the next. Factors to consider are:

- The inertia of the pump the lower the angular momentum of the impeller, motor and the liquid within the pump casing, the greater the potential for a Check Valve to slam.

- The pipeline profile – the higher the proportion of static head vs. dynamic head in a system, the greater the possibility of Check Valve Slam.

- Pipeline diameter the larger a pipeline diameter the longer the travel distance and time for a Check Valve disc to travel hence the greater the possibility to slam.

- Parallel pumping systems if one pump shuts off reversal of flow will be created very rapidly in the common pump header causing the Check Valve to be slammed shut creating inevitably a high pressure rise.

- Column separation rapid flow reversal through the Check Valve will create high pressure transients.

- Surge vessels these devices can cause rapid flow reversal at the Check Valve creating Check Valve Slam.

- Constant speed pumps these pumps are turned on and off at full operating capacity and cannot be ramped up or down like pumps fitted with variable speed drives. In addition, these pumps have low inertias.

Valve Design

Outlined above are factors that can and do lead to high pressure transients upon Check Valve closure. It should be obvious that check valves are not designed equally and therefore react differently to the conditions outlined. Although there is a profusion of Check Valve designs, each with its own design rational, the general consensus from empirical test data conducted over many decades is that a Check Valve must close very rapidly to avoid the destructive phenomenon of Check Valve Slam and all associated pipeline damage.

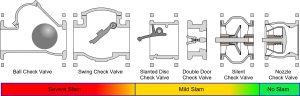

In order to achieve rapid closure, the travel distance of the closing member (disc travel) of a Check Valve must be short with a low inertia and low friction, and the closing motion should preferably be spring assisted.

Designs such as Nozzle Check and Silent Check valves that have a short stroke and are spring assisted have a better ability to reduce or eliminate Waterhammer than any other designs. This can be demonstrated below.

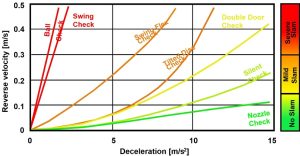

Figure 1 – The calculation of the system deceleration is important to determine whether a Check Valve will slam or not. The deceleration is calculated from the original forward flow velocity and time period when the velocity reaches zero. The maximum velocity of the reverse flow depends on the Check Valve construction and on the system deceleration. The higher the deceleration, the higher the reverse velocity that can develop before the Check Valve closes. Therefore, the higher the Waterhammer transient that will be created.

Nozzle Checks provide the fastest response due to its internal design times and therefore possesses the greatest ability to dampen or eliminate Waterhammer, followed by Silent Check Valves. Based on the graph, we can present the different valve designs and the ability to slam from left to right.

Figure 2 – The distance that the Check Valve closing member has to travel before flow reversal occurs determines the valve’s potential to slam. A Swing Check Valve disc has to travel through a 90-degree angle and is often slammed shut by the reverse water flow. A Nozzle Check Valve is a short and linear stroke. In addition, the closure of the valve is spring assisted, closing in that low milli second time span before flow reversal occurs, thereby preventing Waterhammer.

Nozzle Check Valves vs Silent Check Valves

Nozzle Check Valves and Silent Check Valves are both linear closing spring loaded designs with short closing strokes. It is this characteristic that allows the valves to close in a low milli second time span before flow reversal occurs thereby limiting flow reversal and the potential for Waterhammer.

Both Nozzle designs have become more popular in the South African Water Industry since the 1990’s when the awareness of Waterhammer and its damaging effects on pipeline began to grow as a result of greater access to Surge and Waterhammer analysis software and awareness campaigns headed by manufacturers such as REXUS and, academics.

The growing appreciation from end users and design engineers for the need for a Non-Slam Check Valve design is a positive advancement.

However, there is an observation in several specifications where both Nozzle and Silent Check Valves are specified as if they are interchangeable or, where a Nozzle Check Valve is specified but the Valve vendor has supplied a Silent Check Valve instead.

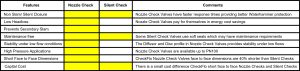

If the selection criteria of the Check Valve is only for quick closure under pump trip conditions, then, either a Nozzle or Silent Check Valve may be suitable. However, if the interest is in the complete Life Cycle Costing of a pipeline, then, there are other criteria to consider such as:

Headloss Characteristics

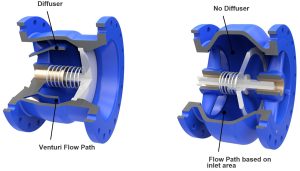

A Nozzle Check valve is based on a Venturi principle where the internal body profile is specifically dimensioned and contoured to match the performance of a Venturi Nozzle. The disc shape and the flow path is such that the flow velocity increases as the pressure reduces towards the Vena Contracta of the valve. At this point the flow path of the valve increases as the velocity reduces, recovering the head across the valve as the flow exits the valve. This results in a low headloss characteristic.

A Silent Check Valve is designed on the principal that the total valve body area, minus the internal components should be equal or greater than the mating pipe diameter. This design philosophy takes the approach that the less the resistance, the less the losses. However, body internal design configuration is equally important. A design that creates turbulence in the flow will in turn generate head loss.

In the case of the Silent Check valve, because it does not have a diffusor to streamline the flow behind the disc as in the case of the Nozzle Check Valve, therefore creates a higher headloss than a Nozzle Check Valve.

Nozzle Check Valve Silent Check Valve

Figure 3 – A Nozzle Check Valve is based on a Venturi design that ensure low headloss characteristics. In addition, the relationship between the Diffuser and the profile of the Disc ensures a rapid response to changes in flow. A Silent Check Valve has no Diffuser and therefore creates higher Headlosses than a Nozzle Check Valve

Face to Face Dimensions

Space in a pump-house is generally limited. The shorter the face to face, relevant to the desired performance of a Check Valve, the more compact the design layout can be. TRUFLO manufactures a short face to face Nozzle Check Valve that is in line with API 594 standards and is available in both wafer and flanged versions. This design is on average 40% shorter than a standard Silent Check Valve but with headloss characteristics that are 30% lower than that of a Silent Check Valve.

Initial Cost vs Life Cycle Costing

It is generally understood that the initial capital cost of the Nozzle Check Valve will be higher than that of Silent Check Valve. The differential in price is dependant on the manufacturer. Most Nozzle Check Valve manufacturers, manufacture primarily for the petroleum and gas industry and sometimes venture into the water industry. The cost differential therefore between their Nozzle Check Valves and a Silent Check Valve is high.

REXUS manufacturers primarily for the Water industry and also manufacturers 100% locally. Further, REXUS manufactures both Ring Disc and Centrally Guided Nozzle Check Valves as well as short face to face and long face to face designs. The cost differential therefore between our Short Face to Face Nozzle Check Valves and our Silent Check Valves are negligible specifically if the Life Cycle Cost benefits of the Nozzle Check design is taken into account.

Spot the Difference

Not all Check Valves are equal. A Silent Check Valve is highly suitable where Waterhammer protection is the prime concern. However, if the design engineer considers the complete Life Cycle Costing of a pipeline system, then a Nozzle Check Valve should in most instances be the preferred choice.

Because a Nozzle Check Valve holds a higher value in terms of capital costs and Life Cycle Costing benefits, manufacturers will at times label their Co-axial Check Valve as a Nozzle Check Valve when in essence, it is a Silent Check Valve. The design engineer can quickly spot the difference by asking the following questions:

How is flow recovered across the valve?

If by a Venturi design, then the valve is likely a Nozzle Check. If by the flow area being equal to or greater than the inlet then, it is likely a Silent Check Valve.

Does the valve have a Diffusor?

If the valve is a Venturi design and has a diffusor then, the valve is definitely a Nozzle Check Valve.

If the design has a diffusor but recovers flow by the area being equal or larger than the inlet then, it is still a Silent Check Valve.

Conclusion

A Check Valve is a critical component on any pipeline project. Both Silent and Nozzle Check Valves are suitable to minimise Waterhammer as they have the fastest response times under pump trip conditions of all check valve designs. In addition, both close silently (hence the name). However, Nozzle Check valves provide a higher performance than Silent Check Valves and are available in shorter face to face dimensions. A quick comparison indicates the differences between the two designs:

Based on the above it is clear that Nozzle Check Valve can be called a Silent Check Valve, but a Silent Check Valve is not necessarily a Nozzle Check Valve. Distinguishing between these two designs makes a big difference when it comes to the Life Cycle Costing of a pipeline system.